| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : JHPD

Model Number : Novel 11

Certification : IATS16949 Certification

Place of Origin : China

MOQ : 1000pcs

Price : Negotiable

Payment Terms : T/T

Supply Ability : 10000pcs/month

Delivery Time : 15-30

Packaging Details : According To Your Demand

Material : ADC12 or others

Logo : Printed or laser with customized logo

Colours : Silver, Black ,Grey

Part name : Engine cover

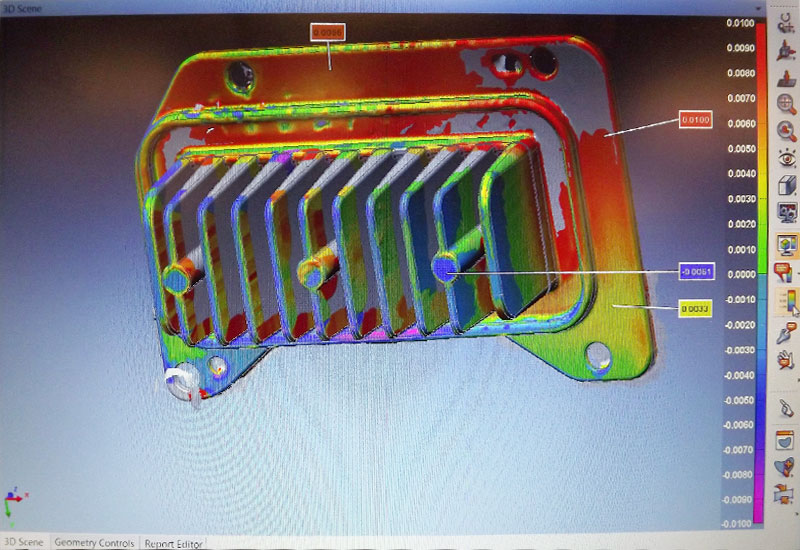

Surface : CNC machine

Lead time : 4weeks

Aluminum Die Casting OEM Manufacturer Customed Aluminium Alloy Engine Cover

| Description: | engine cover |

| Product name: | Customed Aluminium alloy engine cover |

| Material: | ADC12, A380 |

| Logo: | Printed or laser with customized logo |

| Finish: | Painting, Powder spraying , sandblasting |

| Packaging: | Simple EPE bag 12pcs/ctn |

| Colours: | Silver, Black ,Grey |

| Process: | Die casting, Machining,Finish,Inspection, Package |

Our 58 presses range in size from 250 ton to 1250 ton producing aluminum die casting components for low and high volume production programs. JHPD provides high pressure die casting and a range of other die casting processes. Process monitoring, press side imaging, robotics, MAGMAsoft® flow simulation, perpetual tooling, and tool maintenance programs are utilized to extend tool life, reduce cycle times, reduce costs, and provide high quality die castings. From precision aluminum parts manufacturing and prototyping through assembled finished production, JHPD can provide, under one central umbrella, the integrated services required to be your complete global manufacturing resource.

Aluminum die casting alloys are lightweight and possess high dimensional stability for complex part geometries and thin walls. Aluminum has good corrosion resistance and mechanical properties as well as high thermal and electrical conductivity, making it a good alloy for die casting.

Our Alloys Include:

· Aluminum: 360, 380, 383, 413, and ADC12 ,B390

· Zinc-Aluminum: ZA-3# ,ZA-5#

JHPD provides leaders in the electronics industry with electronic design automation (EDA) software to efficiently verify and evaluate their product designs. Our products significantly improve the design-to-manufacturing process, eliminate design iterations, and significantly reduce time-to-market. For printed circuit board (PCB) design, embedded systems development and smart product realization, we provide tools that address the challenges of ever-increasing performance and product complexity.

JHPD offers a variety of packaging options for our customers. We can provide packaging layered or by cell. We cater to individual markets all across the globe, and understand that we may have to create something just for you. That’s why we also offer custom-designed returnable cardboard or plastic packaging.

|

|

ADC12 Sandblasting Aluminum Die Casting Mold Engine Cover ODM Images |